|

|

![]()

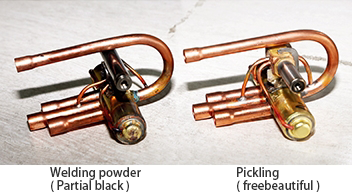

The conventional solder paste flux is usually powder or emulsion, which can not be evenly applied on the surface of the workpiece, and there is usually waste of solder residue during soldering. There will be flux accumulation and oxidation in the area with excessive coating, while the area with insufficient coating will be oxidized. The workpiece usually needs pickling. The pickling free flux is a uniformly clear and transparent liquid (the active material is evenly distributed and will not change with time precipitation). Like the flux cored wire, the amount of flux applied on the workpiece surface can be also controlled, without excessive or waste and is environmental friendly. Compared with flux cored wire, it can ensure the fluidity of workpiece and protect the surface of workpiece from oxidation. Compared with the gas flux, it can be used not only in flame brazing, but also in high frequency brazing, and it is more active.

| Model | Characteristic | Application | Safety technical specification |

| FB501L | Non-corrosive | Flame and high frequency brazing of copper, brass and carbon steel | MSDS |

| FB502L | Corrosive, residues are easy to be cleaned with water | Flame and high frequency brazing of copper and brass | MSDS |

| FB503L | Corrosive, residues are easy to be cleaned with water | Flame and high frequency brazing of copper and brass | MSDS |

| SOLDER POWDER SOLDER PASTE | FLUX-CORED WIRE | NO CLEANING FLUX | |

| environmental protection | × | √ | √ |

| Artifacts protection | × | × | √ |

|

static/file/flv | 325.94KB | Download |