Cu-Al flux cored brazing ring

![]()

The outer layer of the Cu-Al flux-cored brazing material is Zn-Al alloy and the inner layer is a composite brazing material composed of white fluoride flux. The white flux is non hygroscopic, non corrosive and does not need to be cleaned after brazing. At present, it is mainly used in flame brazing, high frequency induction brazing and furnace brazing with copper and aluminum alloy, brass and aluminum alloy, aluminum alloy and aluminum alloy.

Refrigeration industry

FC22S and FC20S contain high-purity cesium fluoride flux, which is non corrosive and highly active, and can effectively remove oxide on the surface of copper tube and aluminum tube. Flux cored wire mainly has three forms:disk, strip and ring. It is the ideal material for brazing copper and aluminum tubes.

| Name | Model | Composition | Brazing powder quantity(wt%) | Diameter(mm) | Inner diameter(mm) | Brazing temperature(℃) | Remark | |||

| Metal | Flux | |||||||||

Cu-Al flux cored brazing ring | XR-FC0215 | Zn,Al, other | Cs-Al-F | 10~20 | φ1.6 φ1.8 φ2.0 φ2.2 | 6.0~20.0 | 420~480 | Standard type, applied to copper and aluminum, aluminum and aluminum brazing | ||

| XR-FC0215A | Zn,Al, other | Cs-Al-F | 10~20 | φ1.6 φ1.8 φ2.0 φ2.2 | 6.0~20.0 | 420~480 | The flux temperature is lower than FC0215,has higher activity and fluidity | |||

| XR-FC22S | Zn,Al, other | Cs-Al-F | 10~20 | φ1.6 φ1.8 φ2.0 φ2.2 | 6.0~20.0 | 420~480 | Can be used with copper and aluminum, aluminum and aluminum brazing, higher strength and conductivity | |||

| XR-FC20S | Zn,Al, other | Cs-Al-F | 10~20 | φ1.6 φ1.8 φ2.0 φ2.2 | 6.0~20.0 | 420~480 | The fluidity is lower than FC22S,suitable for brazing with large gap | |||

| Note: special specifications can be customizedaccording to customer requirements | ||||||||||

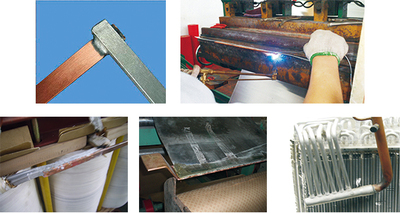

Product form

Product form

Spool,Ring,Rod,Coil

Packing

Spool: 0.5kg/reel 1kg/reel 2kg/reel 5kg/reel

Rod: 1kg/bundle length 500mm 2kg/box

Ring: 0.5kg/pack 1kg/pack 1000pcs./pack 2000pcs./pack

|

|

|